What is ETRA?

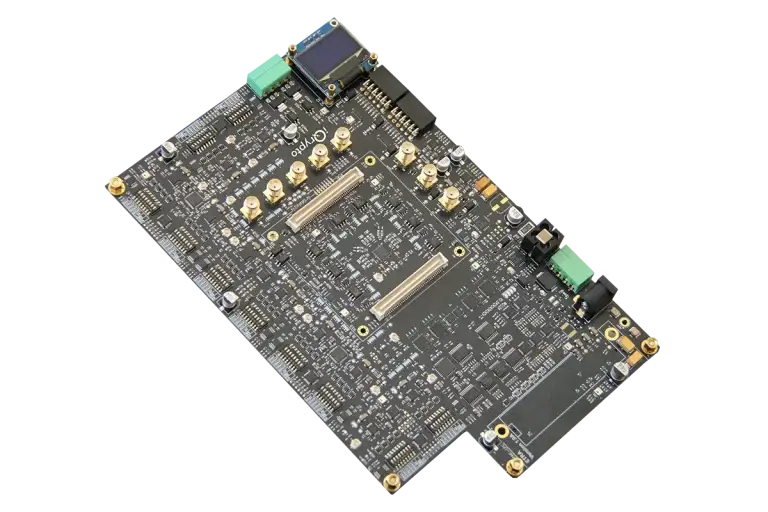

The iQrypto ETRA DAQ is a high-performance, ultra-low-noise data acquisition platform designed to bridge the gap between prototype testing and full-scale deployment. With modular hardware, configurable FPGA functionality, and an intuitive graphical interface, ETRA DAQ accelerates your time-to-market for critical applications across multiple industries.

Why choose ETRA?

Real-Time Precision

Equipped with a 24-bit ADC across 8 analog input channels, the system delivers >30 Gb/s capture bandwidth, ensuring signal fidelity even under complex quantum-level noise conditions

Scalable & Modular

A flexible FPGA-based architecture supports adaptable front-end configurations, enabling engineers to fine-tune voltages, sampling rates, and filters without rewriting code or re-wiring hardware.

Fast Transition

Reusable test pipelines, auto-detection of hardware configuration, and version-controlled metadata accelerate retesting and validation cycles for multiple chip spins or system upgrades

User-Friendly software

Accessible GUI tools enable engineers to visualize, analyze, and export data pipelines in real time—without requiring Python scripting or manual trace configuration.

Specifications

Hardware

Ultra Low Noise IC Voltage Supply – 10-phase voltage 50 mV – 5V

Analog Inpute Channels – 8 channels 24 bit

Capture system – Fully customizable last generation HP FPGA

FPGA Data Capture Bandwith – >30 Gb/s

Software

Data Saving and Management : Persistent storage on SSDs/HDDs, efficient data retrival with ultra-secure measures

Online Measurement and Analysis : Live data visualisation, real-time analysis, and reporting.

Real-Time Data Capture : Continuous 24/7 monitoring and lossless data capturing.

AI and Machine Learning : AI Data Pattern Detection, TensorFlow Integration, Sensor Fusion ready

Ideal Use Cases

Imaging & aerospace instrumentation

Maintain bandwidth and timing precision in environments where low noise and real-time fidelity are critical.Integrated circuit testing & validation

Evaluate CMOS QRNG chips or other analog-digital hybrid systems using configurable signal chains and high-resolution analysis.Research & scientific simulations

Achieve pipeline repeatability, traceability, and retest accuracy for academic or industrial R&D.Sensor fusion & AI detection

Integrate seamlessly with machine learning frameworks (e.g., TensorFlow) for sensor data analysis and predictive modeling.

FAQ - ETRA DAQ

What is a data acquisition (DAQ) system?

A data acquisition system (DAQ) captures analog or digital signals (e.g. voltage, temperature, pressure) from sensors, conditions the signal, and converts it via ADC into digital data for analysis, storage, or real-time control. It includes signal conditioning, ADCs, and software interfaces for visualization or export.

What makes ETRA DAQ different from standard DAQs?

ETRA DAQ combines a high-performance 24-bit ADC across 8 channels, modular FPGA signal conditioning, ultra-low noise capture (>30 Gb/s), and GUI-based real-time software allowing high-speed data acquisition with precision unmatched by common DAQ tools.

How does signal conditioning improve accuracy in a DAQ system?

Signal conditioning like amplification, filtering, linearisation, and calibration—ensures sensor outputs are clean, stable, and digitised accurately by the ADC. This is especially critical for low-voltage or noisy sources like thermocouples or strain gauges.

Which industries benefit most from ETRA DAQ?

ETRA DAQ is ideal for applications in aerospace, imaging diagnostics, integrated circuit testing (e.g. CMOS QRNG), scientific R&D, and sensor fusion projects where high-speed, high-resolution, and modular data capture are essential

How do I choose the right data acquisition system?

Selecting the right DAQ requires evaluating the required accuracy (ADC resolution), sampling rate, channel count, compatibility with sensors and software, scalability (modular or standalone), interface options (USB, Ethernet, FPGA), and noise performance for your application.

Contact us

Want to learn more about ETRA-DAQ, request a demo, or discuss your specific needs in high-precision data acquisition?

Our team is here to support your R&D, FPGA integration, or industrial testing projects.